Why Warmth Transfer Fluid Is Essential for Optimizing Power Transfer in Equipment

The role of heat transfer fluids in enhancing energy transfer is crucial for achieving efficient thermal administration throughout different commercial fields. These fluids assist in smooth warmth exchange, guaranteeing processes operate within ideal temperature level arrays and alleviating the threat of getting too hot. Their selection, based on factors like viscosity and thermal stability, directly influences the effectiveness and sustainability of a system. The complexities of selecting the ideal liquid are commonly undervalued. What are the essential factors to consider for this selection, and just how do they influence both financial performance and ecological duty in industrial applications?

Duty in Thermal Monitoring

Warmth transfer liquids play a critical role in thermal management by efficiently regulating temperature levels in numerous commercial processes and systems. These specialized liquids promote the transfer of warmth in between various elements, guaranteeing optimal operating problems and stopping overheating. By maintaining precise temperature control, heat transfer liquids allow industries such as chemical production, oil and gas, and power generation to run safely and successfully.

The option of an appropriate warmth transfer liquid depends on several variables, consisting of thermal stability, heat ability, and thickness. High thermal security guarantees that the liquid can endure extreme temperatures without weakening, while a high warmth ability allows it to soak up and release significant amounts of warmth - heat transfer fluid. Low thickness lowers the power needed for pumping, adding to overall system effectiveness

Furthermore, warmth transfer fluids are important in applications like refrigeration, where they aid take in and dissipate heat throughout the cooling cycle. In solar thermal power systems, these fluids capture and transportation solar heat to create electrical power or provide warm water. Their versatility to diverse operating conditions and capacity to maintain constant thermal performance highlight their relevance in commercial thermal management, facilitating functional connection and enhancing precaution.

Enhancing System Effectiveness

To maximize the benefits of thermal administration, improving system performance via the tactical use of warmth transfer fluids is extremely important. By maintaining optimal temperature levels, heat transfer liquids aid ensure that systems operate within their designed parameters, thus stopping overheating and decreasing the danger of element failure.

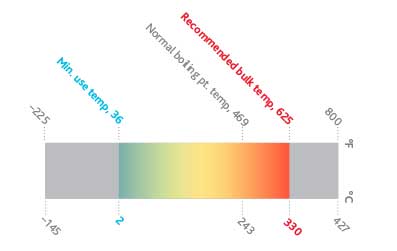

Types of Heat Transfer Liquids

The variety of warmth transfer liquids emphasizes their crucial duty in a series of commercial applications, each customized to fulfill details thermal management needs. These fluids assist in effective energy transfer and are chosen based upon crucial properties such as thermal stability, thickness, and warmth capability. The main types consist of water, glycol remedies, oils, and synthetics, each offering distinctive advantages.

Water is the most common warmth transfer tool because of its high specific heat capacity and inexpensive. Its usage is restricted by its freezing and steaming points. Glycol mixes, typically used in HVAC systems, give a reduced freezing factor, including convenience in different climates. Mineral oils are preferred for their thermal stability and non-corrosive nature, making them ideal for high-temperature applications.

Artificial fluids, consisting of silicone and fragrant substances, provide exceptional thermal stability and are used in settings demanding extreme temperature level arrays. These liquids ensure exceptional performance in systems where standard liquids might view publisher site stop working. The choice of a warm transfer liquid is essential, as it affects system efficiency, safety, and longevity. Each type should be chosen to straighten with the functional needs and the specific conditions of the application it serves.

Environmental and Economic Perks

Utilizing the appropriate warm transfer liquids supplies significant ecological and economic benefits for industrial procedures. Environmentally pleasant heat transfer liquids, commonly naturally degradable and safe, reduce the threat of soil and water contamination in the occasion of leakages or spills, consequently protecting ecological communities and complying with rigid environmental guidelines.

Financially, the best warmth transfer fluid can dramatically decrease functional prices. Reliable heat transfer minimizes power expenditure, causing reduced energy bills and boosted success. In addition, fluids with prolonged lifecycle efficiency decrease the frequency of substitutes and upkeep, decreasing downtime and connected prices. Purchasing high-quality liquids can also reduce the danger of devices deterioration and failing, avoiding costly repair work and expanding the life-span of critical infrastructure. In open markets, these cost savings and performances give a distinct advantage, enabling business to designate sources much more successfully and purchase more innovation. In general, the tactical use of ideal warm transfer liquids sustains sustainable economic growth and environmental stewardship.

Picking the Right Fluid

Exactly how does one browse the complicated procedure of choosing the ideal warmth transfer fluid for industrial applications? Thermal stability makes certain the fluid can endure high temperatures without breaking down, while compatibility stops corrosion or other damaging responses with system components.

Furthermore, the fluid's warmth ability and thickness are critical. A high heat capacity allows the liquid to take in and transfer more power, improving effectiveness.

Conclusion

The strategic option and application of warm transfer fluids are fundamental to enhancing power transfer throughout different systems. By guaranteeing high thermal stability and ability, these fluids provide accurate temperature control and boost general system efficiency. This optimization adds to minimized operational prices and lower greenhouse gas exhausts, therefore promoting sustainability. The selection of fluid, customized to certain viscosity and functional demands, is essential for maximizing performance and achieving economic and environmental benefits in commercial my company processes.

Comments on “Understanding the Role of Heat Transfer Fluid in Reliable Power Equipments”